HPGM Urusyo rwinshi rwo gusya

Gusaba

Mu Bushinwa hari ubwoko bwinshi bw'amabuye y'agaciro, ariko imiterere y'ubwoko bwinshi bw'amabuye y'agaciro ni mibi, itandukanye kandi nziza. Mu rwego rwo gukemura ibibazo bigaragara mu rwego rw’ubukungu, tekiniki n’ibidukikije mu rwego rwo guteza imbere ubucukuzi bw’amabuye y'agaciro, inganda zicukura amabuye y'agaciro mu gihugu zinjiza cyane, zangiza kandi zinjiza ibikoresho bishya byo mu bucukuzi bw'amabuye y'agaciro kandi bunoze. Muri aya masoko, HPGR ni ibikoresho byo gusya cyane kandi byabanje gushakishwa no kwerekana, kandi bitangira gukoreshwa munganda zicukura ibyuma byimbere mu gihugu. Nibikoresho byo gutunganya ibirombe bireba cyane inganda zikora ubucukuzi bwimbere mu gihugu. Birashobora kuvugwa ko HPGR ikoreshwa cyane mu birombe byo mu rugo. HPGR yakoreshejwe cyane mu gihugu no mu mahanga mu gusya mu nganda za sima, guhunika mu nganda z’imiti, no gusya neza pellet kugirango yongere ubuso bwihariye. Ikoreshwa mu kumenagura amabuye y'icyuma kugirango igere ku ntego zinyuranye nko koroshya inzira yo guhonyora, guhonyora no gusya gake, kuzamura umusaruro wa sisitemu, kunoza ingaruka zo gusya cyangwa ibipimo byo gutandukana.

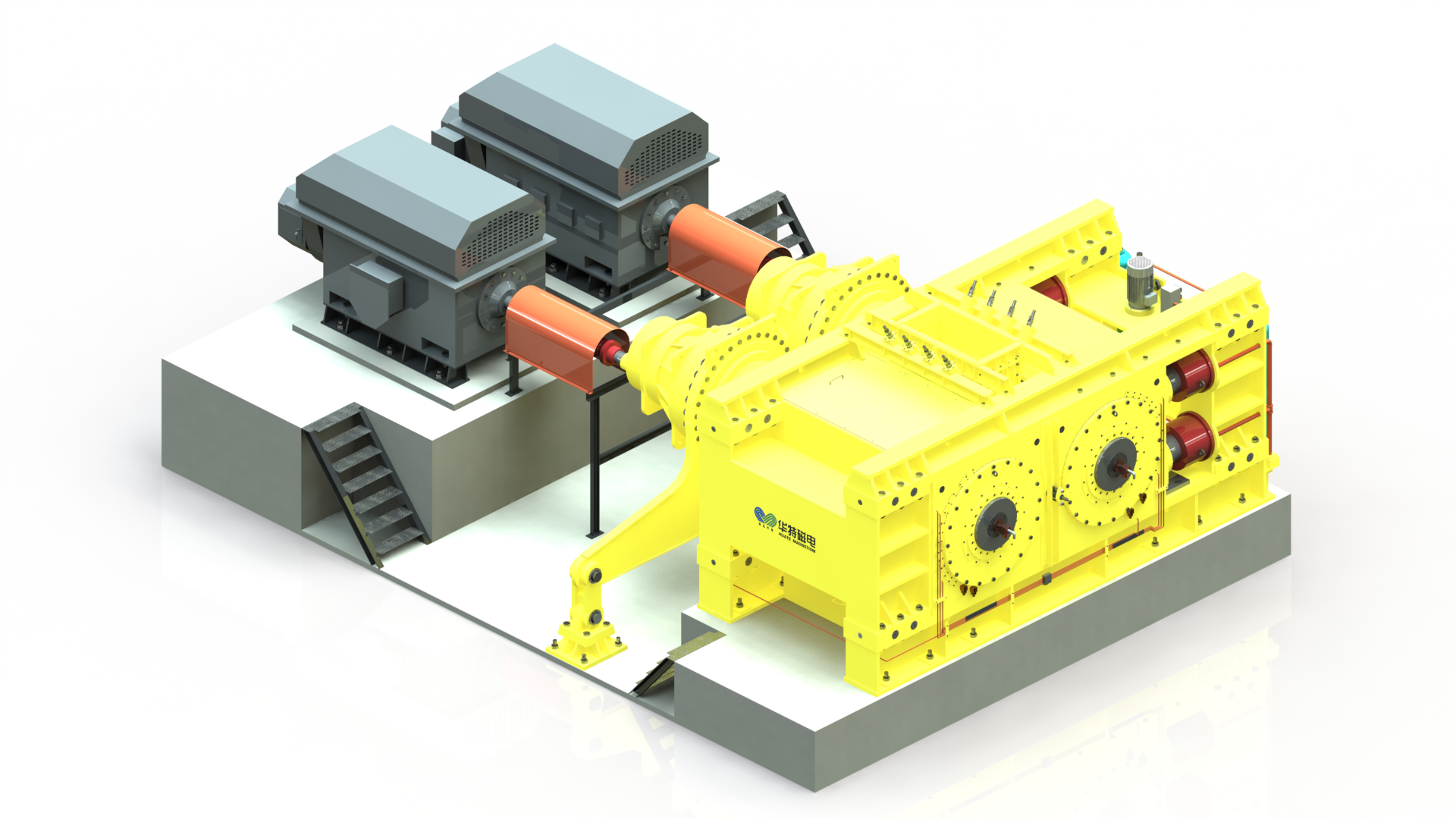

Ihame ry'akazi

HPGM ikurikirana yumuvuduko mwinshi wo gusya ni ubwoko bushya bwibikoresho bizigama ingufu zo gusya byateguwe nihame ryumuvuduko ukabije wibikoresho bya pulverisation. Igizwe nibice bibiri byikaraga bizunguruka icyarimwe kumuvuduko muto. Imwe ni umuzingo uhagaze undi ni umuzingo wimukanwa, byombi bitwarwa na moteri ifite ingufu nyinshi. Ibikoresho biragaburirwa neza uhereye hejuru yimizingo ibiri, kandi bigahora bitwarwa mukuziba kuzunguruka. Nyuma yo gukorerwa umuvuduko mwinshi wa MPa 50-300, cake yuzuye ibintu isohoka muri mashini. Muri cake yasohotse, usibye igipimo runaka cyibicuruzwa byujuje ibyangombwa, imiterere yimbere yibice byibicuruzwa bitujuje ibyangombwa byuzuyemo uduce twinshi twa mikorobe bitewe n’umuvuduko mwinshi, ku buryo ubushobozi bwo gusya ari byateye imbere cyane. Kubikoresho nyuma yo gukuramo, nyuma yo gutandukana, gutondekanya no kwerekana, ibikoresho byiza biri munsi ya 0.8 mm birashobora kugera kuri 30%, naho ibikoresho bitarenze mm 5 bishobora kugera kuri 80%. Kubera iyo mpamvu, murwego rwo gukomeza gusya, gukoresha ingufu zo gusya birashobora kugabanuka cyane, kuburyo ubushobozi bwo kubyaza umusaruro ibikoresho byo gusya bushobora gukoreshwa byuzuye, muri rusange ubushobozi bwimikorere yumupira wumupira bushobora kwiyongera 20% ~ 50 %, kandi ingufu zose zikoreshwa zirashobora kugabanukaho 30% ~ 50% cyangwa zirenga.

Ibyiza byibicuruzwa

Design Igishushanyo gihoraho cyerekana umuvuduko woroshye hagati yizingo kandi bikagira ingaruka zo guhonyora.

Ection Gukosora byikora, birashobora guhindura byihuse icyuho kugirango ibikoresho bigende neza.

Sisitemu yo gutandukanya impande zigabanya ingaruka zingaruka zingaruka.

■ Hamwe na sitidiyo ya karbide, ubuzima burambye bwa serivisi, kubungabunga byoroshye, no gusimburwa.

Bank Banki ya valve yakira ibice byatumijwe mu mahanga, kandi sisitemu ya hydraulic ifite igishushanyo mbonera kandi cyizewe.

系列溢流型棒磨机MBY-G-Series-Overflow-Rod-Mill.jpg)